P-diagram Six Sigma

These are man materials machine methods measurements and mother nature. Annotate Retained and Changed Process Steps Selecting Process Steps for Analysis On Process Flow Map.

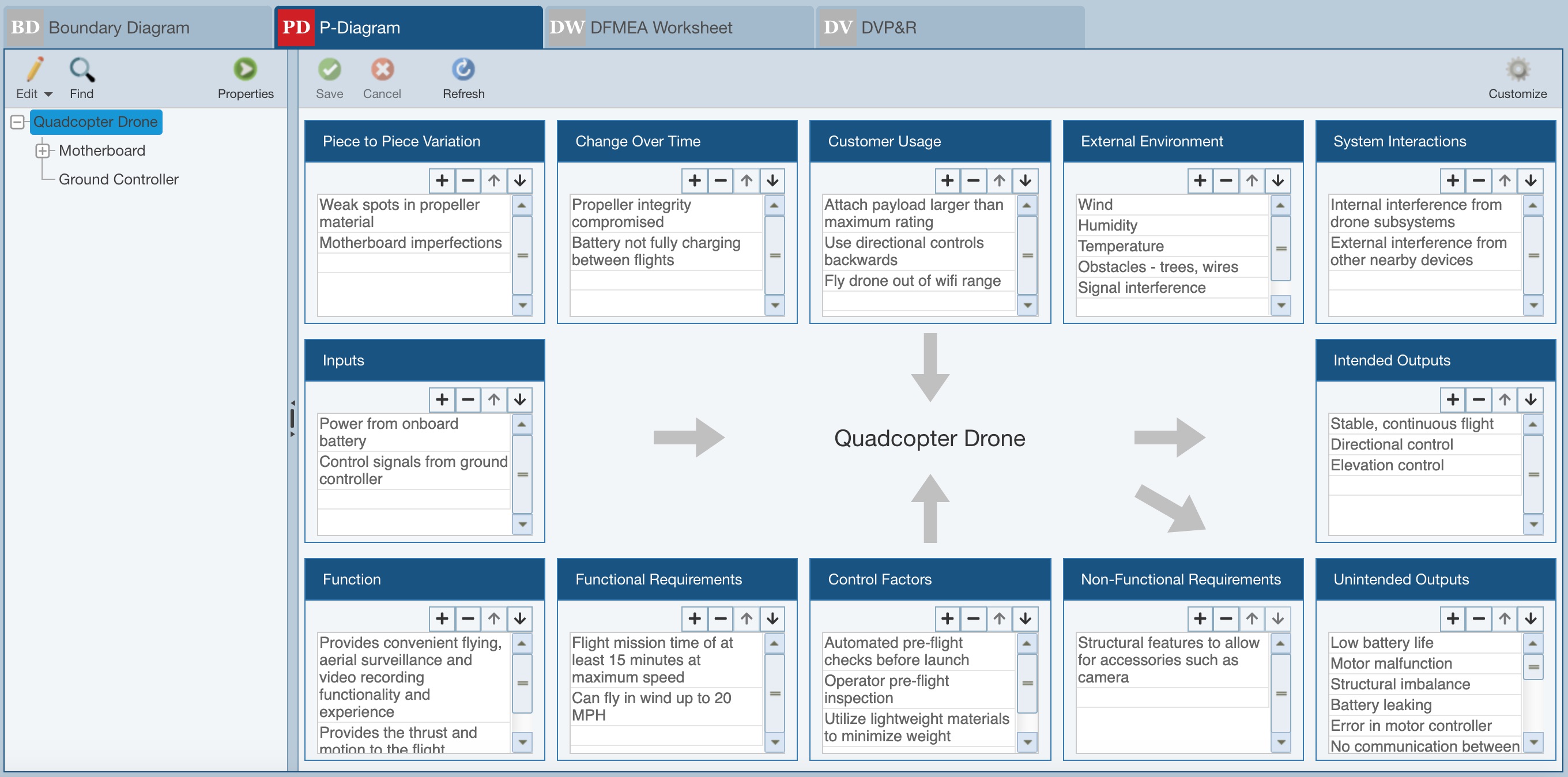

Anticipation Of Potential Problems P Diagrams And Dfmea Applying Design For Six Sigma To Software And Hardware Systems Requirements Flow Down Informit

This Ishikawa diagram is based on the 6Ms of Six Sigma.

P-diagram six sigma. The C chart displays the number of defects. Six Sigma Templates. A six sigma process is one in which 9999966 of all opportunities to produce some feature of a part are statistically expected to be free of defects.

Try It Now Buy Now. Viewing 3 posts - 1 through 3 of 3 total. The NP chart displays the number of defectives.

Following this understanding the paper. Fishbone diagram is also know as. Elements of the P-Diagram Process Flow Diagram.

Six Sigma Approach on Throughput Improvement in the Diffusion Process of Crystalline Silicon Solar Cell. Therefore this paper seeks the knowledge regarding how P-Diagram Model Taguchi Method can be applied in product development stage to achieve Design. Every item in the sample is evaluated for only the number of defects flaws or occurrences etc.

Simple but very powerful. Identify Steps Being Modified Identify New Steps Required for New Product. However if youre not careful you can find yourself spending more time trying to develop these visual representations than working on the actual project.

The use of charts and diagrams to measure data and illustrate concepts is an important part of Six Sigma methodology. In previous articles in this series I introduced Designed Experiments Article 28 and Taguchi Methods Article 32. Anticipation of Potential Problems.

Ellis develops and instructs Six Sigma professional certification courses for Key Performance LLC. If you remember the. It prevents people from focusing on the most obvious cause which is man.

Man Machines Materials Fishbone. The P-chart is the most sensitive attribute chart and is displayed as a fraction or or proportion. System requirement flow-down also involves anticipation of potential problems.

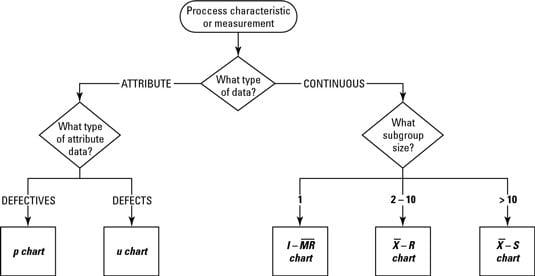

Various business diagram templates on this sharing community are available to download and customize including SWOT matrix marketing diagram fishbone value stream business forms and etc. The p chart is used with a varying sample size where you are counting the number of defectives in the sample. At the system level a P-diagram and FMEA can be part of the concept generation and selection process for the system as described in Chapter 8 and the system-level FMEA is included in the flowchart for identification of critical.

Its one of the oldest and most trusted techniques that charts out a map for Six Sigma projects to critical business processes. The data that used was release packer bag data of cement bag PPC 50kg in Tuban 4 on January to Februari 2015 where the result was p multivariate control chart has not controlled statistically with sigma level on January 2015 was 410 and on February 2015 was 412. The P-Diagram is a useful tool in brainstorming and documenting.

Multivariate control chart sigma level Pareto diagram and Ishikawa diagram. This entry was posted in Six Sigma and tagged DOE P Diagram Six Sigma Taguchi Methods. Juran honored Ishikawa by naming the tool after him and is now also known as the Ishikawa Diagram.

Signal Factors Response Variable or Ideal Function Control Factors. Perbaikan meliputi metode penyablonan dan standarisasi waktu penjemuran. The term SIPOC seems to be an abbreviation of random letters but it is written in a systematic fashion which is relevant to its fundamentals.

Fish bone diagram cause effect diagram or Ishikawa diagram. Fish bone diagram is a scheme that by its structure reminds a fish and its bones what a surprise D. Six Sigma iSixSigma Forums Old Forums General P- Diagram This topic has 2 replies 3 voices and was last updated 16 years 3 months ago by howe.

Input-process-output I-P-O is a structured methodology for capturing and visualising all of the inputs outputs and process steps that are required to transform inputs into outputs. Download scientific diagram P-diagram of the diffusion process. These categories are mostly used to draw a cause and effect diagram in the manufacturing industry.

Diagram p hanya mengakomodir inspeksi dengan dua keputusan OK. Free Download Six Sigma Diagram Templates Online. The p chart is used when the data can only be whole numbers as in counting it is known as discrete also known as attribute data.

In this article I will introduce the Parameter Diagram aka P-diagram and explain how the P-diagram is used in conjunction with Designed Experiments as part of the robust design process. The paper illuminates on Process as the basic unit for Six Sigma and how production process can be enhanced using P-diagram. For a particular interface System in the pictures Item in the FMEA you may have a group of functions that are to be performed These ideal functions are prompted by an input signal.

The first company to adopt the diagram in all of its processes was Kawasaki Iron Fukiai Works in 1952. ANALISA PENERAPAN METODE SIX SIGMA 61 Analisa Hasil Causse Effect Diagram Berdasarkan hasil analisa dengan Causse Effect Diagram dapat bahwa metoda yang digunakan masih belum benar sehingga metoda harus segera dilakukan perbaikan. The SIPOC diagram is a part of the Six Sigma methodology.

There are 3 names of one simple tool. The Fishbone Diagram was originally created by Kaoru Ishikawa to find process imperfections Ishakawa 1985. The U chart displays the number of defects per unit.

For P charts the subgroup size may vary but they should each be 50. Six Sigma 6σ is a set of techniques and tools for process improvementIt was introduced by American engineer Bill Smith while working at Motorola in 1986. The P-Diagram attacks a subset of the elements in the Functional Block causing you to break these interfaces down and analyze them at a lower level.

Therefore this paper seeks the knowledge regarding how P-Diagram Model Taguchi Method can be applied in product development stage to achieve Design for Six Sigma DFSS. Upload your own great works with others and enjoy the resources together. The Parameter Diagram P-Diagram takes the inputs from a system customer and relates those inputs to desired outputs of a design that the engineer is creating also considering non-controllable outside influences.

There is an addressed problem written into the fish head. It is often referred to interchangeably as an I-P-O model or an I-P-O diagram both of which make reference to the intended visual nature of the method. Diagram p adalah jenis diagram kontrol yang digunakan di dunia industri atau bisnis untuk memonitor proporsi dari ketidaksesuaian dalam sebuah sampel di mana proporsi ketidaksesuaian ditentukan sebagai rasio unit yang memiliki ketidaksesuaian dibandingkan dengan jumlah sampel.

Fmea Corner Parameter Diagrams P Diagrams

Green Belt T I Solutions Change Management Six Sigma Tools Lean Six Sigma

Robust Design Taguchi Method Case Studies

Measure Phase Of A Dmaic Six Sigma Project

Solar Farm Introduction To Robust Design Taguchi Method

How To Use Control Charts For Six Sigma Dummies

Robustness P Diagram Overview The Quality Portal

Six Sigma Wikipedia Bahasa Indonesia Ensiklopedia Bebas

Six Sigma Wikipedia Bahasa Indonesia Ensiklopedia Bebas

Sipoc Diagrams Powerpoint Template Slidesalad Powerpoint Templates Powerpoint Business Process Management

Six Sigma Methodology Scope Diagram Template Project Management Business Process Management Education

The 4 P S Of The Toyota Way Applied To Lean Six Sigma International Lean Six Sigma Institute

How To Start Six Sigma Process Mapping Lucidchart Blog

Reviewed by admin

on

February 05, 2022

Rating:

Reviewed by admin

on

February 05, 2022

Rating:

Post a Comment